Ariens Hydrostatic Transmission Problems. Old hydraulic fluid in the hydraulic system is the bfundamentalAriens problem. There may be a hydrostatic failure because of the fluid.

Hydraulic fluid leakage is another Ariens problem that is common. Changing the fluid and fixing hydraulic leaks will deal with them.

My Ariens wasn’t working well. The pressure was not good, and it didn’t move. I checked the fluid that was full and called Ariens customer care for help.

They told me about the transmission issues in Ariens hydrostatic machine. I fixed the fluid issues, and my machine worked smoothly.

Read to learn!.

Ariens Hydrostatic Transmission Problems

Hydrostatic transmission problems aren’t long, but they are problems. The riding mower faces a hydrostatic problem. Replacing the hydrostatic fluid may be a considered opinion.

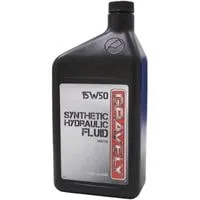

It might even be necessary. Replace the old fluid in the riding mower with a suitable quality fluid and try it. There may be air in the hydrostatic system. The air gets in from several places. Getting the air from the hydrostatic tank and its path will make it work.

The pressure switch pushing the fluid may be broken. The pressure switch is replaceable. They are replacing the pressure switch and will give the fluid enough power to work. The temperature of the hydrostatic fluid may be too high.

The high temperature of the hydrostatic fluid will fail the movement of the fluid and create friction. The inline pressure filters may be clogged. The motor case drains should be checked and troubleshooter further. Read more below.

Fluid problem

The machines using hydrostatic also have hydrostatic fluid in them. The fluid builds pressure when pressed, and the pressure makes the mower move. Not just the mower, but all devices having this system work with the pressure of the fluid.

The pressure of the fluid should be enough to move it, but sometimes the fluid is terrible, and goes bwrongand the pressure is broken. The lack of pressure of the fluid is a problem.

The fluid goes bad after a long time and thus the fluid needs to be changed. You may have put the bad fluid in it without knowing. The bad fluid should be changed ASAP.

The fluid being bad isn’t the only problem you are facing. The fluid can be leaked. There may be a hydrostatic tank leak that causes the fluid to escape and the low level doesn’t allow proper pressure.

To get the proper pressure. Fix the leak and then added good-quality hydrostatic liquid. The rubber seals and the gasket are the ones that actually leak, so check if they are worn. If the gasket is worn, cracks in the oil line affect the pressure of the hydraulic system too.

Pressure switch

There is a pressure switch in some mowers. Not all have the pressure switch, but it’s usually present for safety. The pressure switch acts as a sense. The mower isn’t moved when no one is sitting on it because of the pressure switch.

There isn’t a delay when a person is riding the machine. If you aren’t sitting in the seat of the machine, the machine’s safety will remain on and the machine’s hydrostatic pressure won’t be moved.

Thus you’ll think its problem sitting on the machine will solve the problem. But if the pressure switch is faulty, the hydrostatic pressure will either be released or the machine will keep moving. Fixing the pressure switch if the tractor needs professionals.

Air problem

Air in the hydrostatic system is a negative point. The air disrupts the hydrostatic pressure a lot. The machine doesn’t move if there is air inside the lines. Releasing the air from the hydraulic lines is an option.

To not allow the mower to move while you are fixing, use something like a jack or wooden restraining blockade to save it. Make sure the parking brake of the mower is engaged.

It’s better to put the mower in neutral mode as well. Throttle forward and backward for five seconds and throttle it a few times. The air will go out if you do this.

Now re-engage the transmission to start working. Now test the mower by driving it forward and see if there are any issues left in the movement.

The last word

The machine using hydraulics mechanisms like Ariens is very good. The hydraulic machines may face movement issues because of transmission problems of the fluid. Bad fluid is a considerable cause of it.

If you can fix the fluid and get it in the proper amount, then you can check the pressure and get the air out of the lines too.

As soon as the air gets out of the hydraulic system, the system is completed. The driver belt can be replaced too. Seals that cause the fluid to leak can be released and fixed too.

Related Guides